Bridge Crane & Jib Cranes for Laser Mold Repair – Buyer Guide

5–30 t overhead bridge crane and jib cranes for laser mold & die repair. Buyer recommendations, crane features, precision handling, and safe mold lifting.

Overhead and Jib Cranes (5–30 t) for Laser Mold & Die Repair: Buyer Recommendations

Key Takeaways (Must Read First)

- Selecting the right overhead or jib crane is critical for safe, precise lifting and rotating of heavy molds into laser repair bays.

- Proper crane features, including adjustable height, rotation fixtures, and magnet/clamp attachments, ensure precision positioning for laser welding and repair.

- Using purpose-built cranes avoids damage to high-value molds, enables multi-angle repair access, and improves operational efficiency.

- High-capacity cranes with rotation and attachment options are essential for handling complex mold geometries safely.

Introduction

Choosing the right crane for a laser mold and die repair workshop is more than just picking a lifting device. These cranes aren't moving generic loads—they're handling high-value molds and dies that require precision, stability, and sometimes rotation. A small mistake in lifting or alignment can cause serious damage, lead to costly rework, or even halt your production for hours. That's why understanding which overhead or jib crane (5–30 t) fits your workshop needs is critical.

This guide is designed to help buyers make informed decisions when selecting cranes for laser mold repair, from technical specifications to practical shop-floor considerations. Whether you're upgrading your workshop, planning a new facility, or comparing suppliers, these insights will help you avoid common pitfalls.

Who Should Read This Guide

This information is especially useful for:

- Workshop engineers managing laser mold repair cells.

- Maintenance managers responsible for equipment uptime and safety.

- Facilities managers planning shop layouts and workflow optimization.

- Crane purchasers evaluating suppliers and equipment options for precision lifting.

If you fall into any of these roles, this guide will help you focus on the features and considerations that actually matter, rather than generic specs that look good on paper but don't work in real life.

Why Correct Crane Selection Matters

Selecting the right crane isn't just about handling heavy weights. In a laser mold and die repair environment, the crane must allow for:

- Safe lifting of heavy molds without the risk of dropping or tilting.

- Precise positioning so the laser can reach every angle for welding or surface repair.

- Multi-angle access for complex mold geometries without moving the mold multiple times.

- Efficient workflow that speeds up repair cycles and reduces idle time.

Getting these aspects wrong can lead to damaged molds, longer repair times, and increased costs. On the other hand, the right crane keeps your operations smooth, predictable, and safe.

Application Overview: Laser Mold & Die Repair

In a laser mold and die repair workshop, cranes do more than just lift heavy loads—they are the backbone of precision handling. The molds and dies used in industrial production are often high-value, complex, and sensitive, so moving them safely and accurately is critical. A single slip or misalignment can damage the mold surface, delay repairs, and increase costs.

Cranes in this environment are expected to lift, rotate, and precisely position molds so laser repair tools—welding, cladding, or surface finishing—can reach every necessary angle without repeatedly moving the mold manually.

Key Lifting and Handling Tasks

Cranes in laser mold repair workshops are typically used for:

- Lifting and rotating heavy molds into laser repair bays safely.

- Precise positioning for laser welding, cladding, or surface repair, ensuring accurate alignment.

- Supporting multi-angle access, so the mold can be worked on efficiently from different positions without dismounting.

- Handling frequent loads throughout the workday without overstraining equipment or operators.

These tasks demand not only the right lifting capacity but also rotation and attachment options, such as clamps, magnets, or rotating fixtures, which keep molds secure during complex maneuvers.

Frequency, Load Ranges, and Work Zone Considerations

When selecting cranes, it's important to understand how often molds are lifted and how heavy they are, as this affects equipment choice and workshop layout:

- Load capacity: Most molds in repair operations weigh between 5–30 tons, depending on size and material.

- Lift frequency: Some workshops lift molds multiple times per shift, requiring cranes designed for high duty cycles.

- Work zone layout: Cranes must cover the entire laser repair bay, including space for rotation, maneuvering, and operator access.

- Precision requirements: Laser repairs demand millimeter-level accuracy, so the crane should minimize sway and allow fine positioning.

Small cranes for sale, tailored small gantry crane 2 ton

Crane Types and Their Applications

Selecting the right crane type is critical for laser mold and die repair workshops. Not all cranes are created equal—some are built for heavy, high-throughput bays, while others excel in smaller, more precise cells. Understanding the differences helps buyers match crane capabilities with workshop needs.

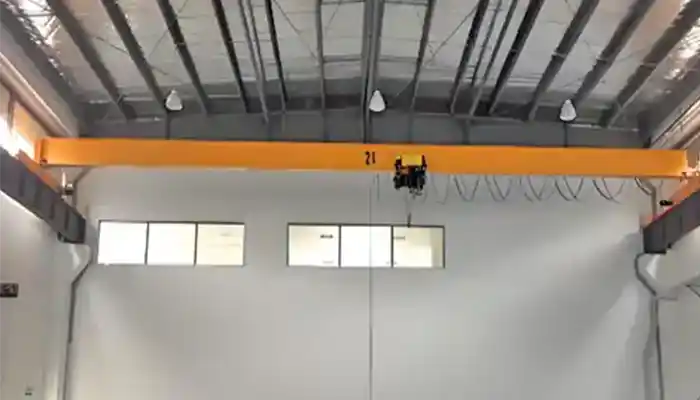

Overhead (Bridge) Cranes

Overview: Overhead, or bridge, cranes are the backbone of many industrial workshops. They run on rails installed above the work area and can cover long spans, making them suitable for high-throughput mold repair bays.

Configurations:

- Single girder: Lightweight, simpler, and cost-effective; ideal for moderate loads.

- Double girder: Supports heavier molds (up to 30 t) and allows longer spans.

- Top-running vs. under-hung: Top-running cranes run on top of the runway beams for maximum capacity. Under-hung cranes hang from the bottom of the beams, saving headroom in low-ceiling workshops.

Advantages for laser mold repair:

- Covers large areas and multiple workstations without moving molds manually.

- Allows multi-angle mold access, improving repair efficiency.

- Supports attachments like rotating fixtures, clamps, or magnets for complex mold geometries.

Jib Cranes

Overview: Jib cranes have a horizontal boom that supports the hoist and can rotate, typically 180° or 360°. They are excellent for localized lifting tasks and small repair cells.

Types:

- Floor-mounted: Strong base, can support heavy molds in specific areas.

- Wall-mounted: Saves floor space, ideal for narrow or confined workshops.

- Mast-mounted: Flexible placement, can serve multiple small workstations.

Advantages for laser mold repair:

- Provides precise positioning for laser welding, cladding, and surface repairs.

- Great for small bays or where only part of the workspace needs lifting.

- Can be equipped with rotating fixtures or magnet/clamp attachments.

Mobile or Gantry Cranes

Overview: Mobile and gantry cranes are semi-portable solutions that don't require permanent overhead runways. They are ideal for workshops that need flexibility or temporary setups.

Advantages:

- Can be moved to different bays depending on workload.

- Supports heavy mold lifting without fixed infrastructure.

- Can integrate rotation or clamping attachments for laser repair.

Practical notes:

- Best for modular workshops or facilities where layout changes frequently.

- Typically limited in speed and precision compared to fixed overhead cranes.

Summary

- Overhead cranes are best for high-volume, multi-angle mold repair tasks.

- Jib cranes excel in precise, localized operations with smaller loads.

- Mobile/gantry cranes offer flexibility for changing workshop layouts or temporary repair cells.

Key Features for Laser Mold Handling

In laser mold and die repair workshops, the right crane isn't just about lifting heavy molds—it's about handling them safely, precisely, and efficiently. Molds are expensive and often complex in shape, so cranes need features that go beyond basic lifting. Here's what buyers should look for when specifying cranes for laser repair operations.

Adjustable Height

Being able to adjust the lifting height is critical. Not all molds are the same size, and laser repair machines often operate at a fixed level. A crane with adjustable height ensures that molds are aligned perfectly with the laser system, reducing the need for additional positioning or supports.

Practical benefits:

- Allows operators to lift molds to the exact working level.

- Minimizes strain on workers moving molds manually.

- Reduces setup time and improves repair accuracy.

Rotating Fixtures

Many molds require access from multiple angles during laser welding, cladding, or surface finishing. Cranes equipped with rotating fixtures allow molds to be turned without detaching them from the hoist. This feature is especially useful for large, asymmetrical, or multi-part molds.

Practical benefits:

- Provides multi-angle repair access without repeated lifting.

- Prevents mold damage from multiple repositionings.

- Improves workflow efficiency by letting operators rotate molds into optimal positions.

Magnet or Clamp Attachments

Securing molds properly during lifting is non-negotiable. Magnets or clamp attachments keep molds firmly in place while moving or rotating them. Choosing the right attachment depends on the mold material, size, and shape.

Practical benefits:

- Ensures molds stay securely fastened, reducing the risk of dropping or shifting.

- Supports handling of irregular or heavy molds safely.

- Compatible with both overhead and jib crane setups.

Precision Controls

Laser repair requires fine accuracy. Cranes with smooth, precise controls—often using variable frequency drives (VFDs), pendant controls, or radio remote systems—allow operators to move molds slowly and accurately. This level of control prevents sway, misalignment, and accidental collisions with workshop equipment.

Practical benefits:

- Enables millimeter-level positioning for laser operations.

- Reduces the risk of mold or tool damage.

- Enhances operator confidence and reduces fatigue during repetitive lifting tasks.

Technical Requirements & Buyer Considerations

When selecting a crane for laser mold and die repair, the technical specifications are just as important as the type and features. Choosing the wrong capacity, span, or configuration can slow down repairs, increase risk, or even damage expensive molds. This section outlines the key considerations buyers should evaluate to make sure their cranes fit the workshop workflow.

Load Capacity

One of the first things to determine is how heavy the molds are and how often multiple molds are handled at once. Most laser mold repair operations involve molds weighing between 5–30 tons, depending on material and size.

Practical considerations:

- Select a crane with enough capacity to handle the heaviest mold plus a safety margin (usually 20–30%).

- Consider batch handling: if multiple molds are lifted at once, capacity must account for combined weight.

- Verify hoist and trolley ratings separately, as both impact lifting performance.

Span, Lifting Height, and Reach

The crane must cover the entire laser repair bay without forcing molds to be moved manually. The span is the distance between rails or supports, the lifting height is how far the crane can raise molds, and reach is how far the load can move along the bay.

Practical considerations:

- Ensure the crane's span matches your workspace and allows access to all repair stations.

- Confirm lifting height aligns with laser machine working levels for precise repair.

- Check that the crane's reach lets operators position molds without excessive handling or repositioning.

Duty Cycle and Service Class

Frequency of use impacts both safety and equipment longevity. Duty cycle refers to how often the crane lifts loads within a set period, while service class defines the crane's suitability for heavy or frequent operations.

Practical considerations:

- High-throughput workshops require cranes rated for continuous or frequent lifting.

- Check manufacturer specifications for duty cycles to ensure the crane won't overheat or wear prematurely.

- Duty class must match workshop requirements; heavy molds lifted multiple times per shift demand higher-class cranes.

Facility Constraints

Your workshop's physical layout also affects crane choice. Headroom, runway structure, and workflow layout can limit the type and configuration of cranes that will fit.

Practical considerations:

- Measure ceiling height and runway beam structure to confirm compatibility with overhead crane designs.

- Evaluate obstructions such as walls, columns, or machinery that could interfere with crane travel.

- Plan workflow so molds can move smoothly between laser stations without bottlenecks or safety hazards.

Workshop Integration & Safety

Integrating an overhead or jib crane into a laser mold and die repair workshop requires more than just buying the right equipment. The physical installation, electrical setup, and safety systems all play a critical role in ensuring smooth, efficient, and safe operations. A crane that isn't properly integrated can create workflow bottlenecks or, worse, safety hazards.

Structural Requirements for Overhead Crane Runways

The crane runway is the foundation of a safe lifting system. Runways must be designed to support the full weight of the crane, the molds, and dynamic loads during lifting and rotation.

Practical considerations:

- Ensure runway beams and supporting structures meet the manufacturer's load specifications.

- Conduct a structural assessment before installation to avoid excessive deflection or vibration.

- Proper alignment is critical for smooth crane travel and precise mold positioning.

Power Supply Compatibility and Control Integration

Cranes require reliable and compatible power connections, and control systems must match workshop operations.

Practical considerations:

- Confirm voltage and phase match your facility (commonly 380–480V, 3-phase, 50/60 Hz).

- Choose a control system that fits workflow needs: Pendant controls for standard operation, Radio remote controls for operator mobility, PLC integration for automated or semi-automated tasks.

- Verify that all electrical systems comply with local codes and standards.

Safety Systems

Safety features are essential for preventing accidents and protecting both molds and operators.

Practical considerations:

- Overload protection: Prevents lifting beyond crane or hoist capacity.

- Anti-sway mechanisms: Keep heavy molds stable during rotation or horizontal movement.

- Emergency stop buttons and alarms: Allow immediate shutdown if something goes wrong.

- Regular inspection of safety devices ensures they are fully functional and compliant with regulations.

Environmental Considerations

Workshop conditions can affect both crane performance and safety.

Practical considerations:

- Dust: Can interfere with hoist mechanisms; consider dust-proof or enclosed hoists.

- Heat: High temperatures may affect electronics and wire ropes; ensure heat-resistant components.

- Ventilation: Good airflow improves operator comfort and helps disperse welding fumes from laser repair.

Overhead vs. Jib Crane Selection

Overhead vs. Jib Crane Selection

When choosing a crane for laser mold and die repair, one of the most important decisions is whether an overhead (bridge) crane or a jib crane best fits your workshop layout and workflow. Each has distinct advantages depending on bay size, lifting needs, and repair complexity. Understanding these differences helps buyers maximize efficiency while keeping costs and safety in check.

Overhead Cranes

Overview: Overhead cranes run on rails installed above the workshop and can span large areas. They are particularly suited to high-throughput laser repair bays where multiple molds need to be handled frequently.

Advantages:

- Supports heavy molds (up to 30 t) and multiple lifts per shift.

- Provides multi-angle access, especially when paired with rotating fixtures.

- Covers large bays, reducing the need to reposition molds manually.

- Can integrate attachments like magnets or clamps for complex mold geometries.

Practical considerations:

- Requires sufficient headroom and a robust runway structure.

- Higher initial investment but often more efficient for high-volume operations.

Jib Cranes

Overview: Jib cranes have a horizontal boom attached to a wall, floor, or mast and rotate around a fixed point. They are ideal for localized lifting tasks or small repair cells where precision and maneuverability are more important than throughput.

Advantages:

- Provides precise positioning for laser welding, cladding, or surface repair.

- Ideal for small bays or single-workstation setups.

- Flexible rotation and compact footprint allow integration into constrained workshops.

Practical considerations:

- Load capacity is generally lower than overhead cranes, typically suitable for smaller molds or light to medium loads.

- Easier to install and maintain compared to overhead cranes.

Footprint vs. Operational Efficiency

- Overhead cranes require a larger footprint and more structural preparation but allow simultaneous handling of multiple molds.

- Jib cranes have a smaller footprint and can be installed in tight spaces but may require more manual handling or multiple units for high throughput.

Total Cost of Ownership

When evaluating cranes, consider more than the upfront price:

- CAPEX (Capital Expenditure): Initial cost of the crane and installation.

- OPEX (Operational Expenditure): Energy consumption, operator training, and workflow efficiency.

- Maintenance costs: Scheduled inspections, spare parts, and service agreements.

A well-chosen crane balances installation footprint, workflow efficiency, and long-term costs, ensuring smooth operations in a laser mold and die repair workshop.

Procurement & Supplier Evaluation

Buying a crane for laser mold and die repair isn't just about picking a model off the catalog. Careful planning and supplier evaluation are crucial to ensure the crane meets your technical needs, integrates into your workshop, and remains reliable for years. A clear procurement process saves time, avoids costly mistakes, and ensures your workshop operates efficiently from day one.

Define Your Crane Specifications

Before contacting suppliers, clearly define what your workshop requires. Detailed specifications make it easier to compare proposals and avoid surprises.

Key specifications to define:

- Lifting capacity: Ensure the crane handles the heaviest molds in your workshop, plus a safety margin.

- Rotation capabilities: Required if molds need to be accessed from multiple angles during laser repair.

- Attachments: Magnet, clamp, or custom fixtures for secure handling of molds.

- Precision controls: Smooth, accurate movement for laser welding, cladding, or surface finishing.

- Duty cycle and service class: Frequency of lifts and intensity of daily use.

Having these specifications ready makes it easier for suppliers to provide accurate quotations and solutions tailored to your workshop needs.

Supplier Evaluation Checklist

Not all crane suppliers offer the same level of quality, support, or compliance. Use the following checklist to evaluate potential suppliers:

- Certifications: Ensure compliance with CE, ISO, or other relevant industrial standards.

- Warranty: Clear coverage for mechanical, electrical, and control systems.

- Spare parts availability: Easy access to replacement parts reduces downtime.

- Installation support: Assistance with setup, alignment, and operator training.

- Experience with laser mold repair cranes: Suppliers who understand mold handling requirements can recommend the right attachments and configurations.

Practical Buyer Tips

- Request detailed drawings or 3D layouts showing crane integration into your workshop.

- Compare total cost of ownership, not just initial purchase price.

- Ask for references or case studies of similar installations to verify supplier reliability.

- Confirm lead times and support options before signing the purchase agreement.

Installation & Commissioning

Installing a crane for laser mold and die repair is a critical step that directly affects precision, safety, and operational efficiency. Even the best crane won't perform well if it's misaligned, inadequately supported, or operated without proper training. Careful planning and commissioning ensure the crane functions reliably from day one.

Pre-Installation Survey and Structural Checks

Before installation, a detailed survey of the workshop is essential. This step confirms that the facility can safely support the crane and that the workflow is optimized for laser repair operations.

Practical considerations:

- Verify runway beam strength and alignment to handle the crane and mold loads.

- Check headroom and ceiling structure to ensure full crane movement.

- Identify potential obstructions such as walls, machinery, or ventilation ducts.

- Confirm power supply and grounding meet crane specifications and local electrical codes.

Installation Stages

Proper installation is a multi-step process to ensure smooth operation and safety compliance:

Key stages include:

- Crane alignment: Rails and beams must be precisely leveled to prevent sway or uneven lifting.

- Load testing: Lift test weights to verify capacity, hoist performance, and structural stability.

- Safety verification: Test emergency stops, anti-sway features, overload protection, and limit switches.

- Functional testing: Run the crane through all travel paths, rotations, and attachment operations to ensure precision positioning of molds.

Operator Training

Even with the best crane, safe and precise operation depends on trained personnel.

Training should cover:

- Safe lifting and rotation procedures for heavy molds.

- Use of attachments like clamps or magnets for secure handling.

- Precision positioning techniques to align molds for laser welding or surface repair.

- Emergency protocols and regular inspection routines to prevent accidents.

Benefits of Proper Crane Selection

Choosing the right crane for laser mold and die repair is more than a technical requirement—it directly affects workshop productivity, safety, and mold longevity. A well-selected crane ensures that heavy molds are handled smoothly, precisely, and without risk, allowing your team to focus on repair quality rather than moving equipment.

Faster Repair Cycles and Improved Workshop Efficiency

Cranes that match the workshop layout and repair workflow help molds move quickly and accurately between stations.

Practical benefits:

- Reduces time spent repositioning or manually adjusting molds.

- Allows operators to perform laser welding, cladding, and surface finishing without interruption.

- Supports multi-mold handling in high-throughput bays, improving overall repair output.

Longer Mold and Die Tooling Life

Safe and precise handling directly contributes to longer life for expensive molds and dies.

Practical benefits:

- Prevents scratches, dents, or warping caused by improper lifting or movement.

- Reduces stress on mold surfaces during rotation or multi-angle access.

- Minimizes downtime due to mold repair or replacement, lowering overall costs.

Safer Operation and Reduced Risk of Mold Damage

Crane features such as rotating fixtures, clamps, magnets, and precision controls enhance safety for both operators and equipment.

Practical benefits:

- Lowers the likelihood of mold drops or collisions.

- Ensures precise positioning for laser repair, avoiding errors that can damage molds.

- Improves operator confidence and reduces workplace accidents.

Why Choose Us

Selecting the right crane supplier can make all the difference in a laser mold and die repair workshop. Our focus is on delivering high-capacity, precise, and safe lifting solutions tailored to the specific demands of mold and die handling. We combine technical expertise, flexible designs, and practical attachments to ensure your operations run smoothly.

High-Capacity Cranes with Rotation and Attachments

Our cranes are built to handle heavy molds and dies (5–30 t) safely, while providing the ability to rotate and position loads exactly where they are needed.

Practical advantages:

- Supports complex mold geometries without repeated handling.

- Integrates rotating fixtures, clamps, or magnets for secure lifting.

- Minimizes mold damage and improves operator safety.

Customizable Solutions

Every workshop has different requirements, so our cranes are designed to be adaptable and tailored to your workflow.

Custom features include:

- Adjustable lifting height for alignment with laser repair bays.

- Magnet or clamp attachments for secure mold handling.

- Rotating fixtures for multi-angle repair access.

- Configurations for overhead, jib, or mobile setups depending on your bay layout.

Designed for Precision, Safety, and Throughput

We focus on building cranes that enhance efficiency without compromising safety.

Key benefits:

- Precise positioning reduces setup time and improves repair quality.

- High-duty construction ensures reliability for frequent mold handling.

- Optimized workflow integration supports faster repair cycles and longer mold life.

Case Studies & Practical Examples

Understanding how cranes perform in real laser mold and die repair workshops helps buyers visualize the right solution for their own operations. Below are practical examples demonstrating overhead, jib, and hybrid crane applications in different workshop setups.

Large Repair Shop: Overhead Crane with Rotating Fixtures

In high-throughput facilities handling 20–30 t molds, a double-girder overhead crane with rotating fixtures proved essential.

Key outcomes:

- Enabled multi-angle access for laser welding and cladding.

- Reduced manual repositioning of heavy molds, saving hours per repair cycle.

- Improved safety, with clamps and magnets securing molds during rotation.

- Optimized workflow by covering the entire repair bay with a single crane.

Small-Cell Laser Repair: Jib Crane for Precise Positioning

For workshops with smaller bays or single-workstation cells, a floor- or wall-mounted jib crane handling molds under 10 t proved highly effective.

Key outcomes:

- Allowed fine-tuned alignment with the laser system for precision repair.

- Compact footprint preserved valuable floor space in small-cell layouts.

- Easy to operate and maintain, with pendant or radio remote controls for safety.

- Supported frequent lifts with minimal setup time.

Hybrid Solutions: Combining Overhead and Jib Cranes

Some workshops benefit from a hybrid approach, combining overhead cranes for heavy, multi-mold lifts with jib cranes for localized precision tasks.

Key outcomes:

- Overhead cranes handle large molds and high-throughput bays, while jib cranes manage fine positioning for specific laser cells.

- Flexible layout allows modular expansion without major infrastructure changes.

- Enhanced safety and efficiency by matching crane type to task requirements.

Practical Takeaways

- Match crane type to workshop size, mold weight, and repair workflow.

- Rotating fixtures and attachments significantly improve precision and reduce mold handling risks.

- Hybrid setups offer flexibility for both high-capacity and precise lifting.

- Always consider footprint, workflow, and operator safety when designing the crane layout.

Summary & Recommendations

Choosing the right crane for laser mold and die repair requires balancing capacity, precision, safety, and workflow integration. The following summary and checklist provide buyers with a practical decision-making framework.

Quick Reference Decision Matrix

| Crane Type | Typical Load | Rotation Features | Attachments | Best Use Case |

|---|---|---|---|---|

| Overhead (Bridge) Crane | 10–30 t | Optional or integrated rotating fixtures | Magnets, clamps, custom fixtures | Large repair bays, high-throughput, multi-mold handling |

| Jib Crane | 5–10 t | Usually limited (180–360° rotation) | Magnets, clamps | Small repair cells, precise positioning, localized tasks |

| Hybrid Setup | 5–30 t | Combination as needed | Custom attachments | Mixed workflows needing both precision and capacity |

Buyer Checklist

When evaluating cranes and suppliers, consider:

- Precision requirements: Ensure the crane allows millimeter-level positioning for laser welding and cladding.

- Safety features: Overload protection, anti-sway devices, emergency stops, and alarms.

- Supplier evaluation: CE/ISO certifications, warranty, spare parts availability, and installation support.

- Facility integration: Adequate headroom, runway structure, power compatibility, and workflow layout.

- Maintenance and lifecycle support: Preventive maintenance, predictive monitoring, and service agreements.

This checklist ensures buyers select a crane that fits their workshop, protects molds, and supports efficient laser repair operations.

FAQ: Questions Solved in This Guide

Q1: How can heavy molds be safely lifted and rotated into laser repair stations?

Heavy molds (5–30 t) are best handled using overhead or jib cranes equipped with rotating fixtures, magnets, or clamp attachments. Adjustable height allows molds to align with the laser system, while precise control systems prevent sway or sudden movement, reducing the risk of damage to molds and workshop equipment.

Q2: What crane features ensure precise alignment for laser welding?

For laser repair, precision is critical. Key features include:

- Smooth, variable-speed controls for millimeter-level positioning.

- Rotating fixtures to access molds from multiple angles without lifting.

- Magnet or clamp attachments to secure molds during positioning.

- Adjustable height to align the mold surface exactly with the laser workstation.

These features together allow accurate, repeatable alignment, improving repair quality and reducing errors.

Q3: Which cranes minimize mold damage and support multi-angle repair?

- Overhead (bridge) cranes with rotating fixtures are ideal for large repair bays handling heavy molds (20–30 t), allowing multi-angle access without repeated manual handling.

- Jib cranes provide precise lifting for smaller molds (<10 t) in single-cell repair bays.

- Using magnet or clamp attachments ensures molds remain secure during rotation, preventing scratches, dents, or deformation.

Q4: How do overhead and jib cranes differ for mold & die workshops?

- Overhead cranes: Best for large bays and high-throughput workflows, capable of handling multiple heavy molds with optional rotating attachments. Requires sufficient headroom and runway structure.

- Jib cranes: Ideal for small cells or localized precision tasks, offering rotation and accurate placement for smaller molds. Compact footprint allows installation in constrained spaces.

- Hybrid setups can combine both to optimize flexibility and efficiency.

Q5: How to evaluate suppliers offering cranes with rotation and attachment options?

When selecting a supplier:

- Verify certifications (CE, ISO) and compliance with industrial standards.

- Check warranty, spare parts availability, and service support.

- Confirm installation support and operator training are provided.

- Ask for case studies or references demonstrating experience with laser mold and die repair cranes.

- Ensure the supplier can customize cranes with rotation, height adjustment, and attachments to match your workflow.

Conclusion

Selecting the right overhead or jib crane (5–30 t) for laser mold and die repair is a critical decision that affects precision, safety, and overall workflow efficiency.

Cranes equipped with adjustable height, rotating fixtures, and magnet or clamp attachments enable multi-angle access to molds while minimizing the risk of damage. Properly matching crane capacity, span, duty cycle, and control features to your workshop layout ensures smooth operations and faster repair cycles.

By carefully evaluating technical specifications, supplier capabilities, installation support, and maintenance plans, buyers can achieve:

- Faster repair cycles and improved workshop throughput.

- Longer mold and die life through safe, precise handling.

- Safer operations for both operators and high-value tooling.

Investing in the right crane solution for your laser mold and die repair workflow is not just about lifting heavy molds—it's about creating a reliable, safe, and efficient repair environment that maximizes productivity and protects your valuable tooling investment.